Detonation is the not so silent killer of rod bearings, pistons, connecting rods, main bearings, crankshafts pretty much anything in its way. Ever since the invention of the internal combustion engine detonation has loomed over engine builders, engineers, and speed demons awaiting its call to smash your dreams to tiny pieces and along with it your bank account.

The good thing is detonation, aka "engine knock" or just "knock", can be avoided with an attention to detail and driver awareness. Modern engine management can even be tuned to aggressively identify and resolve detonation without the driver even being aware of its presence.

Detonation and knock are the same thing.

"Detonation" is the term used in chemistry to describe the combustion behavior, and "knock" is the older and more-commonly used word in the automotive industry. Either is OK to use, and commonly found in ASE materials.

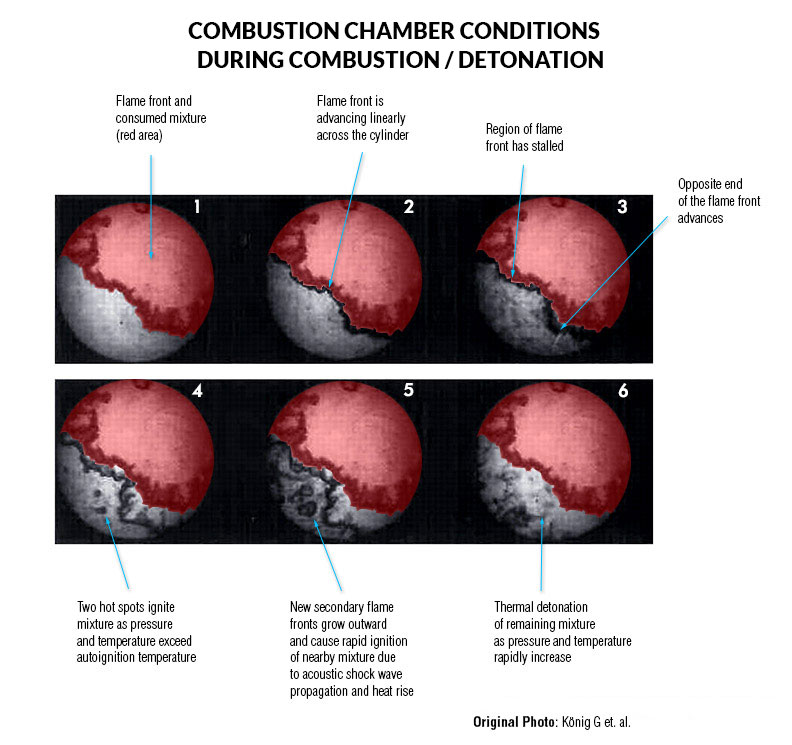

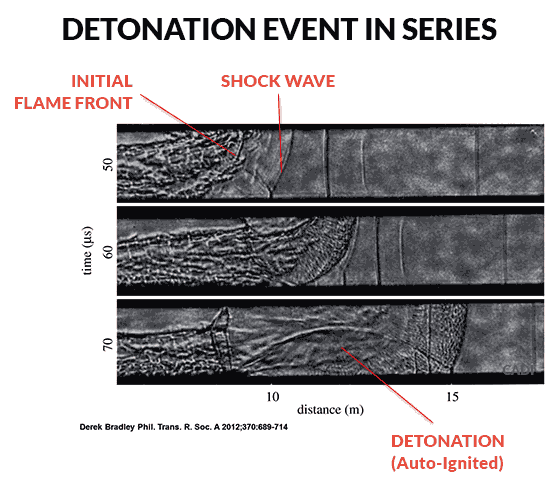

Detonation is when the air : fuel mixture burns at an extremely fast rate due to chamber conditions resulting in multiple flame fronts. Detonation results in a sharp rise in cylinder pressure and temperature far in excess of normal combustion. Detonation can vary in intensity from light, moderate, to severe depending on several factors.

Here's a more technical definition: Detonation occurs after an ignition source, either pre-ignition or the spark plug firing, creates a primary flame front whos acoustic shock wave and thermal gradient kick off auto-ignition in the end-gas (remaining unburnt mixture). This auto-ignition energizes the shock wave further resulting in an exponentially accelerating burn rate. The rate of the primary burn and propagation of the detonation is relative to the homogeneity of the mixture and the sensitivity of the fuel.

Pre-Ignition and Detonation are two different things.

Pre-ignition is not detonation. They are two different things, but often occur together. Pre-ignition is when the mixture is ignited before the spark plug fires. While pre-ignition is often the cause or result of detonation, it can occur by itself in rare circumstances.

Flame Front

This is the edge of the burning mixture. The spark plug fires and the flame radiates outward towards the walls of the cylinder. The leading edge is the flame front.

Consumed Mixture

This is the spent, consumed, burnt air:fuel mixture.

Hot Spot

This is a region of the mixture that is more volatile and nearest to auto-ignition. It can be due to a heated part of the piston or valve, or lesser octane due to fuel quality or oil vapor, or perhaps even both.

Homogeneity

In a perfect world the fuel and air molecules would be evenly distributed in a nice symmetrical pattern throughout the combustion chamber and kept at the same pressure and temperature. This would be a homogeneous mixture. The measure of how close the mixture is to this ideal situation is known as homogeneity.

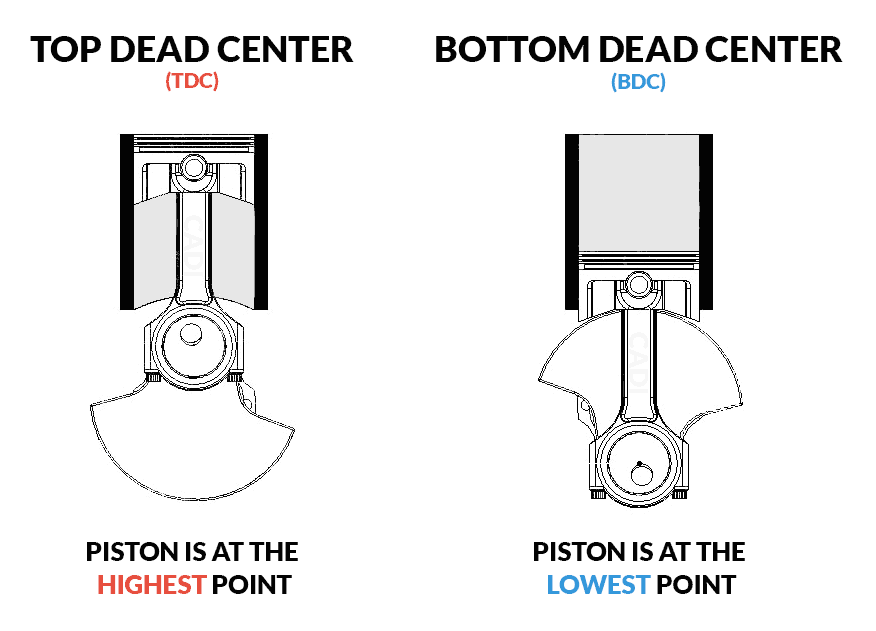

TDC / BDC

Top dead center and bottom dead center. These both relate to the position of the piston in the cylinder. See the below image for more clarity.

The start of the detonation cycle begins with a non-detonation firing event. The spark plug creates a spark at the moment the ECU signals, or the mechanical distributor causes, the ignition to fire. This moment occurs at a calculated or mechanically set point when the piston is still compressing the air : fuel mixture (on the upward stroke).

The spark plug will fire anywhere from 40° to 5° before the piston reaches Top Dead Center, TDC. Since this even is before the piston reaches the top of its compression stroke, its more specifically known as BTDC (Before TDC).

The spark kernal ignites the air : fuel mixture and thus begins the combustion event. The ignition creates the flame front which propagates at a nominal rate outwards. This ideally burns the entirety of the mixture and creates a rapid, but controlled, increase in chamber pressure as the piston is on its downward power stroke. This occurs between the ignition moment and about 30° ATDC (After TDC). Ideally, you want peak cylinder pressure to occur between 14 18° ATDC to maximize the mechanical leverage of the rod and crank positions.

Prior to the piston reaching the bottom of its stroke, bottom dead center (BDC), the exhaust valves will begin to open. The residual pressure in the chamber is high which creates a strong blow-down in the exhaust once the valves reach significant lift (0.050 or 2mm). This allows the chamber to decompress before the upward exhausting stroke, reducing pumping losses. By allowing the exhaust gas to exit over a longer moment of time, the exhaust port can also be smaller in cross sectional size, improving engine performance at lower throttle / lower flow moments.

Once the piston begins its upward stroke, the combined residual pressure and the pressure generated from the decreasing cylinder volume work to expel the majority of the exhaust gasses. Any left over exhaust gas creates dilution in the incoming mixture. This can be good or bad depending on you goal. Bad for power, but good for fuel economy and emissions since it displaces incoming fuel, acts as a defacto displacement reduction, and reduces NOx emissions by reducing the combustion temps; hence the purpose of modern EGR systems. Without getting too far into it, bigger cams create valve overlap which allows the intake pulse to blow down the chamber through the exhaust. It does this by actuating the intake valves before the exhaust valves are closed. As you can imagine, timing and valve position are important.

At this point the combustion chamber has created heated regions of the piston crown, valve, or chamber that will contribute to the next cycles detonation. These are also known as hot spots.

A small fraction before the piston reaches TDC the intake valves begin to open. The incoming air : fuel mixture blows down into the chamber as the piston generates vacuum on its downward intake stroke.

Once the piston reaches BDC it then begins its return; the compression stroke of the drawn mixture. The hot spots in the chamber have begun to warm the incoming air : fuel mixture.

During the compression stroke the piston travels upwards while the cylinder is still filling. The intake valves will begin to close a few degrees past BDC to allow complete cylinder filling. As the cylinder volume begins to decrease the air : fuel mixture is compressed together. This compression causes the molecules to rub against each other, which generates heat.

The heat and pressure continue to build as the piston compresses the mixture. This pushes the mixture closer and closer to its auto-ignition point.

This causes a highly accelerated burn rate which ramps up cylinder pressure and temperature even further, which in turn causes an even faster burn rate. The burn rate moves further and further away from controlled and begins to fall into the explosion category; hence detonation.

To further the carnage the flame fronts slam into each other and cause a sharp, instant rise in cylinder pressure. This shock wave then travels through the piston, wrist pin, connecting rod, and attempts to shove the connecting rod into the bearing surface. The only thing preventing engine failure is about 0.002 of oil film at the rod bearing. Even if this dampens the blow, the force is transmitted to the crankshaft, which creates a sharp torsional and compressive load. This continues as the waves continuously bounce around the cylinder.

This force is transmitted through the entire engine and the harmonic generated is what you hear as knock or ping. The frequency generated is a result of the engine bore and many other measures, but typically is around the 6400Hz range. Its similar in mechanism to the sound generated by an aluminum baseball bat when it makes contact. Its also what the knock sensor is actively listening for to determine the engine is knocking.

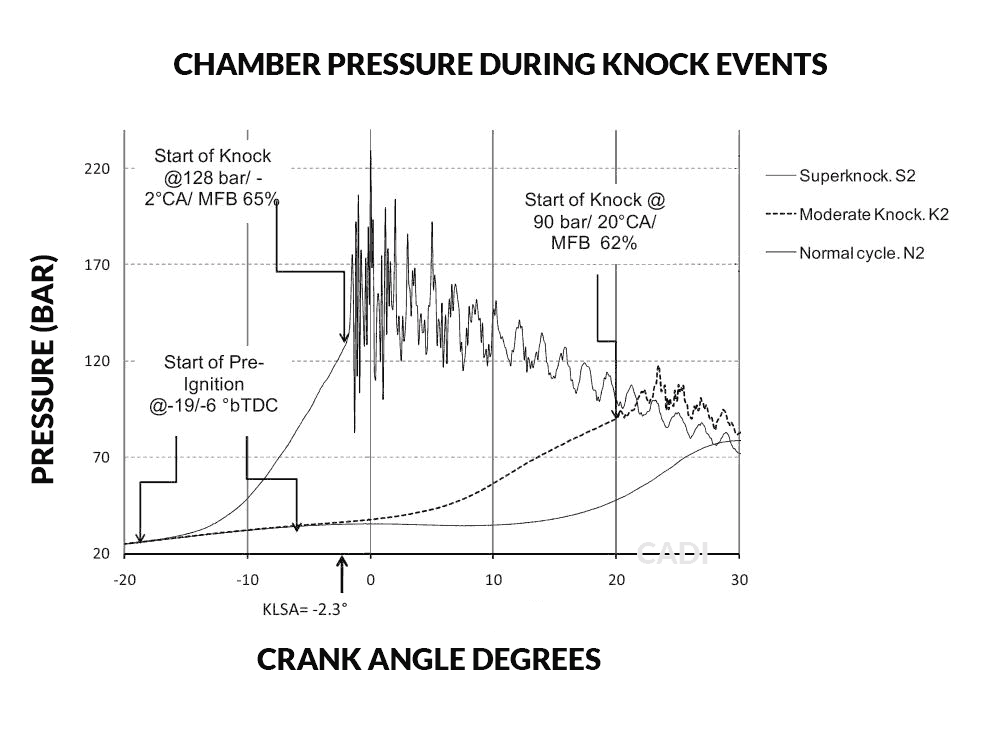

When the knock sensor, a piezoelectric sensor, senses the harmonic (i.e. 6400Hz) it signals the ECU to take action. This action is almost always to reduce ignition timing. Reducing the timing cools the combustion somewhat and gives less time for detonation to occur. If the knock sensor continues to sense knock it will continue to reduce timing further and at a faster rate. This is because detonation needs to be over-corrected due to the added heat causing further and more significant detonation events, even pre-ignition. It may require 3 – 7° of ignition timing correction to tame severe detonation.

Beyond moderate and heavy knock you get into what is known as superknock. When you have superknock it’s questionable if it even matters to reduce timing. Generally you’ve managed to reduce compression via piston ventilation or your connecting rod wants to leave the crankcase.

There are several causes of detonation and each can be remedied multiple ways. Lets break down the individual sources of detonation. It’s important to note that each can be additive or part of the cause. There is no hard and fast rule for it.

A very common cause of detonation is running too much ignition advance. This causes long burn times during critical moments where charge density is highest and the burn rate is at its peak. Aggressive timing advance increases pressure and heat while the mixture is being compressed. This can cause the remaining mixture to detonate.

While less likely to occur compared to overly advanced ignition timing, running severe amounts of ignition retard provides a long window for hot spots in the chamber to pre-ignite the mixture and cause two asymmetric flame fronts, often resulting in detonation.

This is a bit of a silent killer. Most people associate low RPM with being easy on the motor and in most cases they are right, but low RPM also equates to longer windows of time for detonation to occur. The faster the piston travels, the quicker you get away from the high compression moment and the less time the mixture is subjected to heating from hot sources in the engine. In tuning, this is most of the reason why you need to slowly add back ignition advance as the engine RPM rise.

Adding high load (or high boost pressure / WOT) greatly increases the chance and severity of detonation. This is why nearly all OEMs recommend avoiding heavy acceleration in the lower half of the RPM range.

Most people express compression ratios using the static compression ratio generated by the reduction in total cylinder volume (head volume + deck height volume + swept volume) from BDC to TDC. However, the dynamic compression ratio is more complex, but is a better representation of the actual compression ratio.

Dynamic compression ratio uses the rod length, stroke, and rod angle, known as the rod to stroke ratio, or rod ratio for short, to determine the physical location of the piston when the intake valve closes. This begins the real measure of the compression ratio.

As an example, a stock engine with a 10.5:1 static compression ratio may have a dynamic compression ratio of 8.0:1, but adding a higher duration camshaft can lower this dynamic compression ratio to around 7.7:1. This is why big camshafts necessitate higher static compression ratios, to help offset the original loss.

Anything that alters the intake valve timing will also change the dynamic compression ratio. This includes secondary cam lobe profiles like those used on Honda’s VTEC as well as cam phasing technologies like BMW’s VANOS and Subaru’s AVCS. It’s important to adjust ignition timing to meet the needs of advancing or retarding the intake valve’s timing. Here’s the rule for cam phasing:

Intake Cam Advance – This will close the intake valve sooner in the compression stroke. Advancing the intake cam will raise the dynamic compression ratio. This means you need to run slightly less ignition timing.

Intake Cam Retard – This will close the intake valve later in the compression stroke. Retarding the intake camshaft will lower the dynamic compression ratio. This means you need to slightly increase the ignition timing.

The 30° of intake advance range on the 08+ Subaru EJ257 engine will increase the dynamic compression ratio 1.33:1 at full advance.

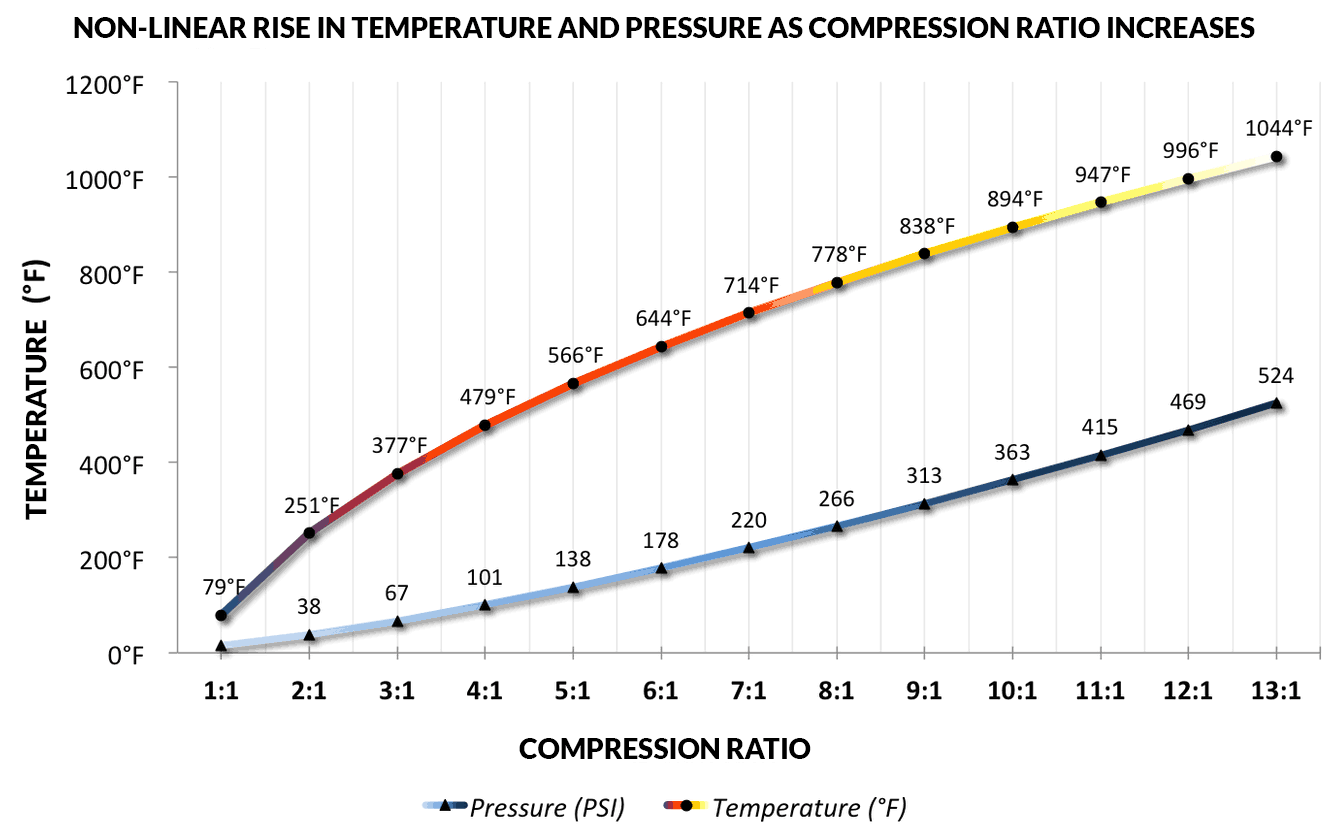

One thing to keep in mind is that compression ratio does not linearly increase pressure and temperature. As the graph below will show, there is an increasing rate of both pressure and temperature rise as the dynamic compression ratio increases.

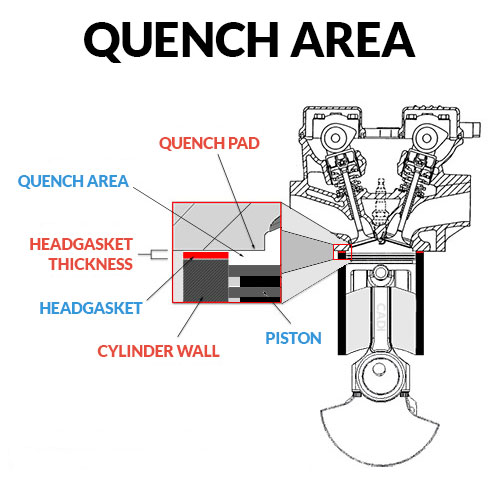

Running a considerably thicker headgasket opens up the area between the piston crown and pads on the combustion chamber, known as the quench area. The quench area is collaborative region between the cylinder head’s chamber design and piston crown. It relies on the attached boundary layer of molecules on both surfaces to displace virtually all of the air : fuel mixture inwards. This reduces chamber volume, which increases thermal efficiency. The quench effect also reduces the likelihood of detonation by creating large amounts of turbulent flow in the mixture, reducing available areas for hot spots, and reducing the distance the flame front needs to cover (which requires less timing advance).

Typical quench spacing is about 0.040 or 1mm.

In most engines, the coolant passes first through the block and then to the cylinder heads. This reduces the available thermal capacity and cooling ability of the fluid at the combustion chamber and exhaust ports. Which in turn raises the temperature of the combustion chamber, leading to greater mixture heating and the reduction in detonation threshold.

During sustained, high load situations the coolant can begin to boil within the cylinder head(s). While a small amount of nucleate boiling is beneficial to cooling, there is a point where the vapor barrier builds and greatly reduces the cooling ability of the coolant. This will create a localized hot spot and most assuredly will cause detonation and/or pre-ignition.

It goes without saying that a bad tune is going to cause problems for you and the engine. This is why you should always go with a tuner that has a wealth of knowledge and experience. While every engine operates within the realm of physical law, it is beneficial to have specific knowledge about the ECU parameters, how the ECU handles and reacts to those parameters, locations of key sensors, and all of the little quirks and issues of the vehicle being tuned.

Octane rating is a measure of a fuel’s detonation threshold relative to reference fuels: n-heptane and iso-octane. The lower the octane rating, the more likely the fuel is to detonate.

Alcohol based fuels like E85 can have misleading fuel octane ratings depending on the source or methods. E85 is 85% ethanol and 15% gasoline, sometimes referred to as "gasahol." Ethanol and methanol have a major benefit over gasoline: charge cooling. Ethanol and methanol, upon injection, will greatly reduce the temperature of the incoming air. Thus, the performance of ethanol in a limited, lab-based octane test is going to be understated, particularly for high-boost engines.

Octane numbering is not a perfect measure. In fact, two 100-octane fuels can have considerably different detonation limits. Different blends and chemical compositions can reduce detonation in some engine setups.

The fuel at gas stations is stored in an underground tank. These tanks are typically sealed from the elements by covers, but these covers can be damaged, worn, or improperly sealed which allows water and runoff to enter the tank.

Alcohol’s affinity for water causes it to separate from the gasoline, which reduces the overall octane rating of the fuel. The water can also interact with the gasoline and further cause complications. The result is lower than expected performance and a high amount of detonation (knock).

Another cause of “bad gas” is due to either mistakes or deception within the supply chain. Refineries make mistakes that can cause entire batches of fuel to be contaminated. Fuel wholesalers and suppliers can make errors when filling the tanks, inadvertently putting a lower octane fuel into the higher-octane tank. Store-owners can also engage in deceptive tactics such as diluting high-octane fuel with low-octane fuel to improve profit margins on pump sales. Fortunately, these incidents are fairly rare.

An issue particularly troublesome on high RPM and high boost motors is aerated oil vapor being blown back through the intake track via the positive crankcase ventilation, PCV, system. The oil has a significantly lower auto-ignition temperature and will ignite early causing detonation in sufficient volumes.

The oil comes from the high-pressure power stroke bleeding gas past the compression rings (rings #1 – 2) and down into the crankcase. The crankshaft is spinning at a high rate of speed, which creates a very turbulent environment of air and fine oil droplets known as “windage.” These droplets coat the cylinder walls and help to cool the engine and lubricate the pistons, but they also get blown down through the PCV.

On modern vehicles, the PCV is routed back to the intake tube where the blow-by vapors are consumed by the engine. Typically this is not an issue, but in sufficient volumes it can be. This is why air : oil separators are installed on performance engines which are particularly prone to these issues.

Ironically, there are rumors that the Mercedes AMG F1 team used octane-boosting agents in the motor oil to use it as a fuel, and possibly as a power adder.

When an engine is spark advance limited (due to detonation), it's common to enrichen the fuel mixture beyond it's ideal ratio to reduce detonation via cooling and sub-optimal mixture quality. For example, if an engine makes peak output at 12:1 but occassionally knocks, it can be tuned to 11.8:1 or 11.6:1. This will have a smaller affect on the power output than reducing the ignition timing.

AFRs are also relative to their calibrated fuel. This is why Lambda is a popular measure in engine tuning.

Over the decades combustion chambers have evolved from large, slow burning designs like the publically popular “HEMI” chamber to smaller, faster-burning, pent-roof designs. This has greatly improved detonation resistance and allowed for much higher compression ratios in modern engines along with improved fuel economy.

A slow burning chamber requires significant amounts of timing advance. Where a modern engine may use 20 – 25° BTDC an older chamber may use 40 – 45° BTDC. This gives significantly more time for detonation to occur.

Another consideration for older cars and trucks are iron cylinder heads. Ductile iron is incredibly resilient, especially with heat, but it also doesnt conduct heat anywhere near as fast as aluminum. The result is less cooling of the combustion chamber and a greater chance for knock to develop with high amounts of continuous load or spark advance. Its common for iron headed motors to run a degree or two less timing.

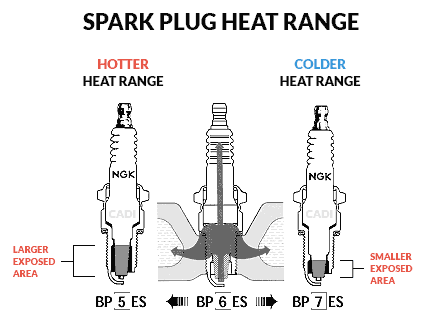

Spark plugs are rated in their ability to shed / resist heating from the combustion process. This rating is known as a heat range.

Colder Heat Range plugs have less exposed area, thus they absorb less heat from the chamber and remain cooler. They will reduce detonation, but too cold of a plug can cause other issues like misfiring, lower performance, and fouling.

Hotter Heat Range plugs have more exposed area, thus they absorb more heat energy and run warmer. They will increase the chance of detonation, but a sufficiently hot plug is needed to maintain a healthy combustion cycle.

Each plug manufacturer has their own heat range scale. NGK for example offers a BKR5E plug which has a heat range of 5. An NGK BKR6E plug is one step colder with a heat range of 6. The BKR5E is standard on the naturally aspirated 140 HP Nissan SR20DE engine, but the BKR6E is the standard plug for the turbocharged 205 HP Nissan SR20DET engine.

The higher the temperature the more likely detonation is to occur. For naturally aspirated engines the major source for hot air is the engine bay. Running an open element intake under the hood ensures you will be feeding heated air to the engine. Even with a basic air box or divider the IATs will climb.

For supercharged and turbocharged engines the issue is much more dynamic. The air entering the air filter might be 100° F on a spring day, but after being compressed that temperature can exceed 400° F at high boost pressures. Fortunately, intercooling is far more popular and prevalent. An intercooler can shed off a large portion of that heat and get the air back down around 120 - 130° F, but it eventually will begin to warm up and lose efficiency.

Known as heat soak, the amount of heat energy being pumped into the intercooler is greater than the amount it can shed to the air or water passing through its core. Eventually the boost temperatures will rise. You could see 130° F turn into 230° F rather quickly with some stock intercoolers. This is when detonation is more likely to occur.

This is what happens when you are driving a car hard or "beating on it."

The piston, chamber, coolant, oil, and intake air will begin to warm up the longer you drive the car hard. This makes detonation more likely, and in some instances, almost guaranteed.

Race cars and high end OEM sports cars go to great lengths to reduce thermal creep and even tune to accomodate it. Unfortunately most street cars don't have adequate protections against thermal creep and as a result, can suffer engine failure if driven long enough.

Follow these tips for reducing knock.

One of the easiest ways to avoid detonation is to retard the ignition timing. This is what the ECU does when the knock sensor senses detonation.

If you are driving a car with a 7000 RPM rev limit, avoid flooring it anywhere below about 3200 RPM. Downshift and use the powerband. Lugging the engine around at low RPM isn’t preserving your engine.

If you can tune the engine’s cam phasing, then you will want to either reduce timing, enrichen the mixture, or close the intake valve a bit later. If you can’t, then just be careful about how much throttle you give it while the intake cam phasing is advanced. Typically this shouldn’t be a problem unless you’ve modified something, and at that point, you really should be getting a tune.

This is a commonly overlooked or misunderstood area of engine tuning with amateurs. That's why it's important to go with an experienced and well-informed tuner.

Here are some tips while building your motor:

Subaru WRXs and STis have a relatively high piston failure rate due, in part, to the complexity and design of the power unit and the driving habits of their owners. Here’s an analysis of certain driving conditions that present an ideal foundation for detonation.

Learn more about turbo Subaru ringland failure in the EJ25

Stuck in Traffic + Sudden Acceleration

You’ve been stuck in stop and go traffic for 30 minutes, but suddenly you reach your exit and you go for it. You drop the hammer in 2nd gear and the EJ257 goes to work. Problem is … the 180° F air your turbo is ingesting is coming out of the turbo at over 400° F. That hot air is being fed to a heat-soaked, top-mounted intercooler (TMIC), which hasn’t had time to cool after being cooked under the hood. The result is feeding your engine 350° F air at 15 PSI of boost pressure. Add in additional compression from the AVCS cam phasing and you can see just how easy it is to grenade those brittle hypereutectic pistons.

High Speed Runs

You’re out on a cool night and you run into a Mustang that wants a piece of you. You start off in 2nd gear and the race is on. Third gear goes by and then 4th gear, it’s neck and neck and you go into 5th gear. After being heated from the quick sprint through 2nd – 4th gears the continuous load during 5th gear will add more and more heat to the system. At this point, the tune comes into play.

Ignition timing needs to decay the longer the car stays into boost to accommodate the rising temperatures from the intercooler heat soaking and the combustion chamber rising in temperature. Many OEMs work this into their algorithmic tuning parameter(s), as does Subaru. As the coolant temperatures rise the ECU will begin to reduce timing. Unfortunately the Subaru system does not use a post intercooler temperature sensor and in most cases light detonation will begin to occur. If you stay in the throttle the car will be noticeably heat-soaked and feel flat as well. Ideally, the fuel mixture should be enriched to further reduce chamber heating. Aftermarket tuners can even trim individual cylinders and adjust timing / fueling depending on gear. It’s common for 5th and 6th gears to have reduced total ignition timing.

On modified cars, depending on the mods, the car can quickly develop heavy knock and cause ring land failure. Certain mods like radiators, intercoolers, oil coolers, etc. will help prevent detonation in this case.

Be mindful of how much heat you’re asking the engine to work with. After you’ve run it hard it’s a good idea to cruise a bit at speed to let the built-up heat escape via the heat exchangers. An intercooler can shed heat very quickly, in a matter of seconds at highway speeds, but the oil and coolant both may need a few minutes to settle back.

Don’t vent the breathers to the open air. You want to maintain vacuum on the crankcase and heads as this improves ring seal, power, and efficiency. Venting oil vapor under the hood is also just a bad idea. Instead, plumb an effective air : oil separator canister inline to strip the oil vapor out of the breather gasses and run the cleaned air back into the intake tract.

There are other methods for pulling vacuum on the crankcase such as going to a multi-stage dry-sump, vacuum pumps, or plumbing the PCV system to a shallow angle feed in the exhaust and relying on the Bernoulli effect to pull vacuum. These are meant for specific applications and should be installed by experienced builders.

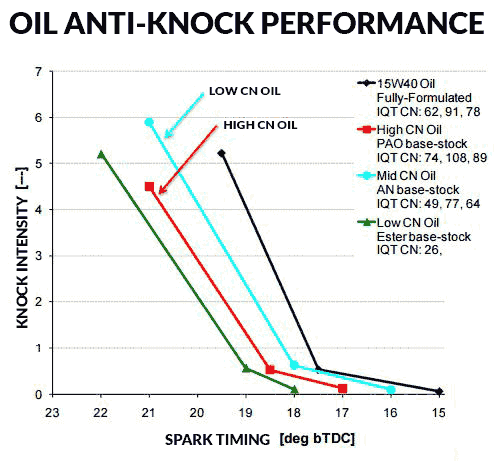

Synthetic PAO oils found in Group IV have about 10% higher auto-ignition temperatures than conventional oils. The ester based Group V stock oils have higher auto-ignition temperatures compared to synthetic oils, which offers slightly more safety against oil vapor induced detonation and pre-ignition.

Even High Grade Oil can Reduce Knock!

In US Government backed testing ester Group V oil allowed for an additional 1.5 of timing advance before knock developed compared to 3 other PAO Group IV oils.

High performance oils also help to reduce friction and cool key components in the engine. In the event of detonation, its absolutely vital that the motor oil be capable of doing all that it can to absorb the blow. This involves proper flow and a stable profile to maintain pressure at all temperature ranges, especially elevated ones. The oil film is all that stands between detonation and bearing failure.

I cannot stress this enough. A good tuner will not only get more power out of a setup, but they will do so safely.

Radiators, oil coolers, and intercoolers are all absolutely vital to keeping your engine happy. Just because your coolant temps or charge temps are OK putting around town or ripping through a gear or two does not mean they are adequate! Ideally, you should be able to beat on the car for minutes and see very manageable temperatures.

It's also vital that you give your heat exchangers a good, clean, and well-ducted stream of air flow.

Look into it for any forced induction application or big bore N/A motor. It cools the inlet charge and is very tolerant of timing.

There are a multitude of causes that generate detonation, and each has a specific fix, but the modal tone behind knock mitigation is simply to reduce the total amount of heat inputted into the engines cycle and slow the combustion rate down. While this ultimately limits an engines specific output and fuel economy, it greatly enhances the longevity of the motor. However, there are many things that can be done to raise the detonation threshold with careful design and implementation of engine systems.

Preventing Subaru Ringland Failure in the WRX, STI, etc.

Subaru Equal vs. Unequal Length Headers

Car Overheating? Learn to Diagnose, Fix, and Prevent It

We are constantly looking for new content ideas and feedback from the community. Head over to our contact page and send us an email with your ideas, comments, or questions.

Join our email list to be notified when we release new content.

We respect your inbox and send only 1 - 4 emails per month.

We will never spam, sell, or do annoying things with it ... ever.